Capacitor on single phase motor may have failed.

Electric motor amp draw test.

Some of newer vehicles can be a real pain to diagnose parasitic draw test with a multimeter due to all the added electrical circuits computers and control modules.

Three electrical windings on the outer part of the motor enable the central rotor to turn otherwise they would simply vibrate moving backwards and forwards as the current alters direction.

When a system has been renovated and system performance has been maximized it s common to read amp draw at 80 to 90 of fla on a most direct drive residential units.

When an electric motor fails to start runs intermittently runs hot or continually trips its overcurrent device there my be a variety of causes.

The amount of energy.

You have electric mirrors heated memory seats gps trackers and a slew of gadgets.

Test it with the multimeter before and after unplugging.

Check c to e s to e r to e.

For example let s find the current draw in amps of a 1 horsepower motor that runs at 120 volts with a 90 efficiency.

To check the capacitor set the volt ohm meter to rx100 scale and touch its probes to the capacitor terminals.

Verify the amp draw of motor versus the nameplate rating.

The goal of the test i ll present here is to compare the measured amps that the motor is using to the fla capacity of the motor.

Motor overloaded or jammed.

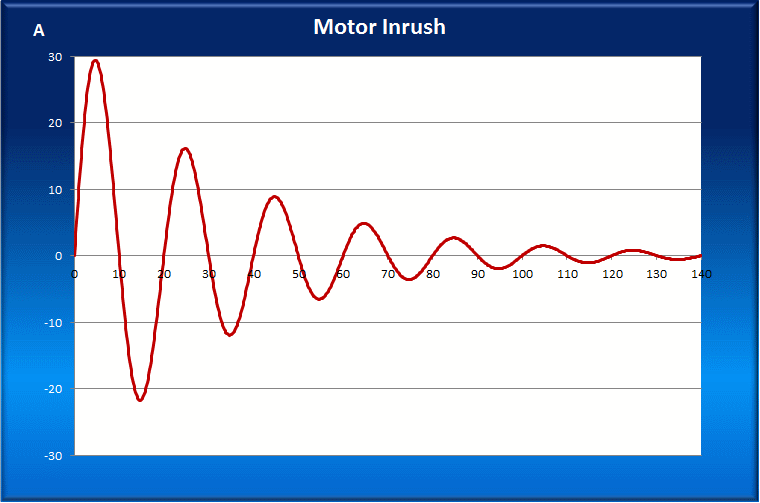

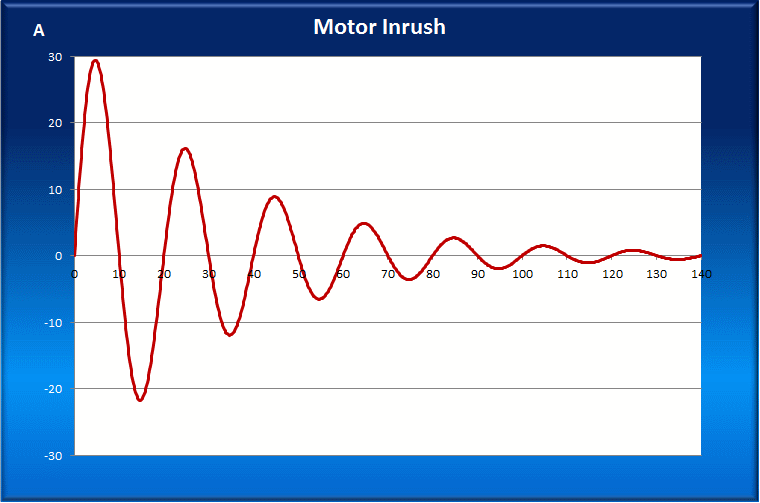

See figure 3 below the 50 load point due to reactive magnetizing current requirements power factor degrades and the amperage curve becomes increasingly non linear.

Electric motor wiring 480 volt electrical motor wiring data nema amps starter size hmcp size for motors ranging 1 2 to 500 hp.

An ac motor uses alternating current to power it and ac current changes directional flow 50 times a second.

Another possibility is that the driven load is jammed binding or mismatched.

Once you have determined the rating you want to make sure you do not exceed 80 of that rating.

Inspect to see that the load is free.

Dc motors full load currents full load amps in 120 and 240 volts dc motors.

This applies to any circuit breaker.

For example if it is a 20 amp breaker you do not want the amp draw to exceed 16 amps 30 amp breaker should not exceed 24 amps.

Deviations from rated fla could signify problems with the motor under test.

In the low load region current measurements are not.

See what the amp rating is on the breaker.

Sometimes the trouble lies within the power supply including branch circuit conductors or motor controller.

Minimum test value for a good electric motor is at least 1mω running amps test with the motor running check the full load amps fla with a suitable meter or preferably a clamp on meter and compare with the motor name plate fla.

First discharge the capacitor.

Amps 1 hp 746 w 120 v 9 amps 746 120 v 9.